DIAMETRAL PITCH KNURLS

American Standard ASA B94.6-1984 describes the diametral pitch knurl system. Diametral pitch knurls are designed to track uniformly on fractional size stock up to 1" in multiples of 1/32" or 1/64". They are held to closer tolerances for this purpose.

| D.P. | Blank Diameters for Uniform Tracking |

| 64 | every 64th inch |

| 96 | every 32nd inch (also every 1/96th in. - .0104) |

| 128 | every 64th inch (also every 1/128th in. - .0078) |

| 160 | every 32nd inch (also every 1/160th in. - .00625) |

The number of teeth that will be rolled can be easily determined by multiplying the blank diameter by the Diametral Pitch of the Knurl. Example: A 96 D.P. Knurl will roll 96 x 1/2 = 48 teeth on 1/2" Diameter stock.

See Table I for equivalent TPI of D.P. Knurls.

CIRCULAR PITCH KNURLS

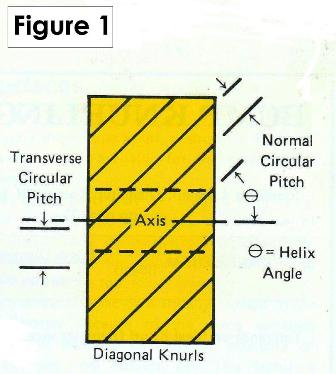

The circular pitch knurl system is

the older system and has been in use many years. The spacing of the teeth

is measured by the number of teeth per inch (TPI) around the circumference.

On diagonal and diamond knurls, the TPI is usually measured normal (or

perpendicular) to the teeth. See figure (1). The

Normal TPI

= 1/Normal Circular Pitch.

Normal TPI

= 1/Normal Circular Pitch.

The Transverse TPI = Normal TPI x cos (Helix angle)

"Form Rol" Diamond and diagonal knurls are specified by their normal TPI (except for KPR & KPL 214, 221, 233, 235, which are made to be equivalent to "P&W" and "Armstrong-Williams" Transverse Knurls).

Determining proper blank diameters for circular pitch knurls is more difficult and is usually accomplished by trial and error. The TPI of circular pitch knurls is only approximate and cannot be used to accurately pre-determine blank diameters.

For Straddle Knurling From the Turret, chances are 90% or more that a given pair of knurling tools can be made to track uniformly with proper set up and adjustment of the holder. With this method of knurling, the tools are already in their final position in relation to the root diameter of the part. When the knurls are fed onto the blank, a fairly large impression is made on the first revolution, which makes it easier for the tool to track properly on the second revolution even though the initial spacing wasn't perfect. If mistracking occurs on the diamond knurling from the turret, it can be corrected by swiveling the knurl which is mistracking approximately 1 or 2°. This would not be noticeable on the finished part.

For Bump Knurling from the cross-slide, the random chance proper tracking on a given blank is somewhat less, mainly because the size of impression made by the tool on the initial revolution is normally smaller than that made by the turret knurling. Sometimes stoning a small flat on the crest of the knurl, or increasing the infeed rate will eliminate a tracking problem, as both of these steps will give larger impression on the first revolution.

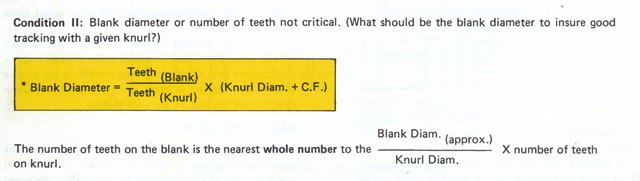

If it is necessary to roll an exact number of teeth, or be sure in advance that a knurl will track well on a given blank, and one of the Diametral Pitch Knurls is not suitable, use the following formulas.