(for Knurls and Blanks up to 1")

Example (1) What Knurl (approx. 5/8" Diam.) would be required to roll 18 teeth on 3/8" diam. blank (approx. 15 TPI) by bumping from the cross-slide?

(Closest stock knurl is GKS-216 - 31 Teeth) Table III.

Knurl Diam. (ideal) = .375/18 x 31 - .010

= .646 -.010

= .636 +/- .7 (.010) x .625/.375

= .636 +/- .012

Therefore a GKS-216 Knurl (.625 Diam.) would be near the low limit of the tolerence of the ideal knurl diameter. It would most likely track properly, but to be more certain, either order a special knurl diameter +/- 1/2 the above tolerance, or if possible change the blank diameter. (In this case a .369 blank diameter would give the ideal knurl diameter of .625.

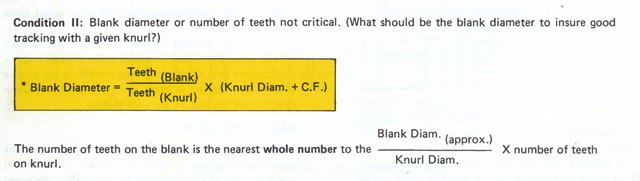

Example (2) To What Size should 1/2" stock be turned to insure good tracking with a KPS-220 Knurl (3/4" Diameter, 47 teeth, 20 TPI - Straight Knurl) bumping from the cross-slide.

Teeth on Blank = .500/.750 x 47 = 31.3 (round to 31) Blank Diam. = 31/47 x (.750 + .007) = .499 +/- .001

Therefore a KPS-220 knurl will roll 31 teeth on 1/2" stock without turning it down.

The proper blank diameter for rolling 30 teeth would be 30/47 x (.750 + .007) = .483

Somewhere between .483 and .499 double tracking would probably occur.

*Note: These formulae apply accurately only to knurls bumped from the cross-slide.